AUTO BODY

CAR BODIES

(b) Hatchback - A saloon with a door at the back is called hatchback. (Wagon R, Swift, i10)

(c) Coupe - In this type there is only one row of seats for two persons. Only two doors are provided. An ordinary saloon with roof-line at decreased height is also called coupe sometimes. The term G.T. ( grand touring ) added to coupe means a car performance which is better than average.

(d) Limousine - Large. Six-seater or bigger passenger compartment and often driven by a chauffeur. Driving compartment is separated from the rear compartment by a sliding glass division.

(e) Fast back - The roof slopes down at a smooth angle to the tail of the car there is no separate door at the rear end.

(b) Convertible - The roof in this is of soft folding type and windows of special wind-up desingn. With these provisions the car may be either open or enclosed.

(d) Coupe convertible - A type of convertible coupe with a rigid roof that can be retracted inside the lower part of the vehicle body.

(b) Sports Utility Vehicle (SUV). A vehicle having large treys, higher seating and more ground clearance. Engine area is separate, but passenger and luggage area are enclosed together. Usually, these have a 4 wheel drive system or an option for the same (CRV, Safari, Grand Vitara, Pajero).

(b) Truck - These are heavy googs commercial vehicles with all the axles attached to a single frame. Generally twin wheel are fitted on the non- steered axles. Depending upon the load capacity, there are two or more axles.

(d) Toures - With extremely large fairings and bodywork, these bikes have a very upright and comfortable riding position.

(g) Moped - With a lower capacity engine , usually 50 cc, mopeds are a hybrid between bicycle and motor cycle.

Closed cars:

(a) saloon or sedans - Has two or four doors, a single compartment with two rows of seats and a fixed roof which is at full height upto the rear windows. There is a separate luggage space usually at the rear. The term saloon is British, whereas sedan is used in USA. ( CITY, D ZIRE)

(b) Hatchback - A saloon with a door at the back is called hatchback. (Wagon R, Swift, i10)

(c) Coupe - In this type there is only one row of seats for two persons. Only two doors are provided. An ordinary saloon with roof-line at decreased height is also called coupe sometimes. The term G.T. ( grand touring ) added to coupe means a car performance which is better than average.

(d) Limousine - Large. Six-seater or bigger passenger compartment and often driven by a chauffeur. Driving compartment is separated from the rear compartment by a sliding glass division.

(e) Fast back - The roof slopes down at a smooth angle to the tail of the car there is no separate door at the rear end.

Open cars:

(a) Sports - The term commonly used fro a relatively small, low slung car with a high performance engine and excellent handling.

(b) Convertible - The roof in this is of soft folding type and windows of special wind-up desingn. With these provisions the car may be either open or enclosed.

(c) Cabrio coach or Semi-convertible - A vehicle with a roof, where a retractable textile cover often acts as a large sunroof. An old style. Is found rarely in modern cars.

(d) Coupe convertible - A type of convertible coupe with a rigid roof that can be retracted inside the lower part of the vehicle body.

Special styles:

(a) Estate Car/Station Wagon - A saloon car with the passenger roof extended right up to the rear end. Rear door for loading with rear seats usually collapsible.

(b) Sports Utility Vehicle (SUV). A vehicle having large treys, higher seating and more ground clearance. Engine area is separate, but passenger and luggage area are enclosed together. Usually, these have a 4 wheel drive system or an option for the same (CRV, Safari, Grand Vitara, Pajero).

BODIES FOR TRANSPORT VEHICLES

Examples of such vehicles are vans, trucks or lorries, buses, coaches etc. A brief description of each type follows.

(a) Van - These are light transport vehicles. There are seats at the from and the luggage space at the rear. The side doors are usually of sliding type. The rear door is used for loading or unloading.

(b) Truck - These are heavy googs commercial vehicles with all the axles attached to a single frame. Generally twin wheel are fitted on the non- steered axles. Depending upon the load capacity, there are two or more axles.

(c) Articulated vehicle - This is also a heavy goods vehicle consisting of a tractor and a semi-trailer. The tractor provides the motive power while the trailer carries the goods. The two units are connected together by means of a fifth-wheel cooling this type of vehicle has smaller turning circle than the rigid truck. Moreover, the trailer being detachable, the tractor can directly move off after reaching destination with some other trailer unit without having to wait for unloading and re- loading. However , in there is less traction available. Moreover steering is more difficult as the trailer wheels do not follow the same path as the tractor wheels.

(d) Bus - These are used for carrying large number of people over distances often in a dense traffic. Not much space for luggage is provided, but there is adequate visibility for the passengers to know where they have to get down. Usually there are two doors, the one at the rear for mounting and the one at the front for getting down. Sometimes, the buses have two floors. Such buses are called double-decker buses.

(e) Coach - These are used for transporting passengers over long distance and are therefore provided with luxurious interior with comfortable, adjustable seats amenities like video.

TWO-WHEELER BODIES

(a) Standard like - Basic from of the motor cycle, also known as street bike.

(b) Cruiser - The bikes wherein the riding position with the hands up and the feet forward with the spine erect, is quite comfortable for long distance riding.

(c) Sport bike - Also called performance bikes , these are much lighter and samaller than than the cruisers. During driving the rider has the hands low, feet backwards and the spine inclined forward.

(d) Toures - With extremely large fairings and bodywork, these bikes have a very upright and comfortable riding position.

(e) Sprort Tourers - A hybrid between sport bikes and Torturers, it makes convenient long distance travelling at higher speeds.

(f) Scooters - These are two-wheelers with smaller wheels, small engines and a configuration which allows the rider to drive with both feet on a running board and knees together.

(g) Moped - With a lower capacity engine , usually 50 cc, mopeds are a hybrid between bicycle and motor cycle.

NUMBER AND ARRANGEMENT OF ENGINE CYLINDERS

Based upon the number and arrangement of cylinder, automobile engines may be classified as:

1. Single cylinder engines

2. Two cylinder engines

3. Three cylinder engines

4. Four cylinder engines

5. Six and eight cylinder engines

6. Radial engines

These will now be discussed in detail.

SINGLE CYLINDER ENGINES : A single cylinder engine has a power stroke every 720 of crankshaft oration for a four-stroke engine. These are used generally for scooters and motorcycles. It is seen that the maximum size of the signal cylinder engine is restricted to about 500-600 c.c., because of the higher unbalance forces, which become difficult to be balanced. Further the weight of the fly wheel required becomes excessive for height engine sizes.

TWO CYLINDER ENGINES: This type engine, apart from providing more power, gives more uniform torque and balancing possible is also better as compared to single cylinder engines. However, in practice two cylinder engines are rarely employed for automotive three different types of 2-cylinder engines.

(A) In-line type cylinders placed side by side. This type has two single cylinders placed side by side vertically so that their pistons are in phase. Such an engine will have a power impulse every 360 degrees of crankshaft rotation.

(B) In-line, cylinders 180 out of phase. In this the two single cylinders are in effect, placed side by side vertically, so that their cranks are 180 out of phase. This type provides good balancing, but the disadvantage is in unequal firing intervals: the spark takes place at 0 , 180 , 720 , 900, and so on.

(C) V-type. In this two cylinders are placed with their center lines at some angle to each other. Generally this angle is kept 60 , but in some instances angles from 40 to 90. Have also been used.

(D) Horizontally opposed type. The two cylinders are arranged horizontally opposite each other, as shown in this type power impulses occur at even Intervals of 360 of crankshaft rotation. As is evident from the figure, the Piston and the connecting rod movements are identical, i.e. both the pistons approach TDC and BDC posi-tions together. This causes the engine to be perfectly balanced, as regards the reciprocating forces. But because the two cylinders are not in line, the forces in the rods produce a rocking couple, in the vehicle. This hinders proper streamlining of the car.

THREE CYLINDER ENGINES : In-three-cylinder in-line engine the power impulse occurs every 240 of crankshaft rotation. These are dynamically balanced, but there remain some unbalanced rocking forces. However, the three cylinder ders smooth out the cyclic torque adequately so that this has becimb a good improved fuel consump-tion. Maruti 800 vehicles in India employ this engine.

FOUR CYLINDER ENGINES: In this type, the torque obtained, as compared to a single cylinder engine, is much more uniform because two working strokes per revolution are obtained. Further, the balancing is also better. Apart from this, the maintenance is also easier as compared to the engines with larger number number of cylinder.

SIX AND EIGHT CYLINDER ENGINES: Fom higher h.p. and smoother torque, the six and eight cylinder engines have been used. Like the four -cylinder engines, they have also been designed in the from of in-line, V-type and opposed type configurations. In six-cylinder in-line engine, there is a power impulse every 120 of crankshaft rotation. Commonly employed firing order is 1-5-3-6-2-4, whereas equally suitable firing order also used in 1-4-2-6-3-5. This engine has smoothness of torque and excellent dynamic balance. For this reason its use is quite common for engine sizes larger than 2.5 litres, provided length of engine is not the main consideration. V-8 engines with smaller V-angles, say 20 , have also been made. The advantages of narrow V are less torsional vibrations and increased stiffness. However, the valve-operating mechanism is complicated.

RADIAL ENGINES : In this case the various cylinder are arranged in radial directions. About the crankshaft which is placed at the number of cylinders generally used is odd, say 5,7,9stc., To obtain uniform firing intervals. This type of engine is compact and gives higher B.H.P./ weight ratio. The construction is also simpler. However, this engine had a very large frontal area, which crests difficulty in streamlining the vehicle shape.

1. Single cylinder engines

2. Two cylinder engines

3. Three cylinder engines

4. Four cylinder engines

5. Six and eight cylinder engines

6. Radial engines

These will now be discussed in detail.

SINGLE CYLINDER ENGINES : A single cylinder engine has a power stroke every 720 of crankshaft oration for a four-stroke engine. These are used generally for scooters and motorcycles. It is seen that the maximum size of the signal cylinder engine is restricted to about 500-600 c.c., because of the higher unbalance forces, which become difficult to be balanced. Further the weight of the fly wheel required becomes excessive for height engine sizes.

SINGLE CYLINDER ENGINES

TWO CYLINDER ENGINES: This type engine, apart from providing more power, gives more uniform torque and balancing possible is also better as compared to single cylinder engines. However, in practice two cylinder engines are rarely employed for automotive three different types of 2-cylinder engines.

(A) In-line type cylinders placed side by side. This type has two single cylinders placed side by side vertically so that their pistons are in phase. Such an engine will have a power impulse every 360 degrees of crankshaft rotation.

(B) In-line, cylinders 180 out of phase. In this the two single cylinders are in effect, placed side by side vertically, so that their cranks are 180 out of phase. This type provides good balancing, but the disadvantage is in unequal firing intervals: the spark takes place at 0 , 180 , 720 , 900, and so on.

(C) V-type. In this two cylinders are placed with their center lines at some angle to each other. Generally this angle is kept 60 , but in some instances angles from 40 to 90. Have also been used.

(D) Horizontally opposed type. The two cylinders are arranged horizontally opposite each other, as shown in this type power impulses occur at even Intervals of 360 of crankshaft rotation. As is evident from the figure, the Piston and the connecting rod movements are identical, i.e. both the pistons approach TDC and BDC posi-tions together. This causes the engine to be perfectly balanced, as regards the reciprocating forces. But because the two cylinders are not in line, the forces in the rods produce a rocking couple, in the vehicle. This hinders proper streamlining of the car.

THREE CYLINDER ENGINES : In-three-cylinder in-line engine the power impulse occurs every 240 of crankshaft rotation. These are dynamically balanced, but there remain some unbalanced rocking forces. However, the three cylinder ders smooth out the cyclic torque adequately so that this has becimb a good improved fuel consump-tion. Maruti 800 vehicles in India employ this engine.

THREE CYLINDER ENGINES

FOUR CYLINDER ENGINES: In this type, the torque obtained, as compared to a single cylinder engine, is much more uniform because two working strokes per revolution are obtained. Further, the balancing is also better. Apart from this, the maintenance is also easier as compared to the engines with larger number number of cylinder.

FOUR CYLINDER ENGINES

SIX AND EIGHT CYLINDER ENGINES: Fom higher h.p. and smoother torque, the six and eight cylinder engines have been used. Like the four -cylinder engines, they have also been designed in the from of in-line, V-type and opposed type configurations. In six-cylinder in-line engine, there is a power impulse every 120 of crankshaft rotation. Commonly employed firing order is 1-5-3-6-2-4, whereas equally suitable firing order also used in 1-4-2-6-3-5. This engine has smoothness of torque and excellent dynamic balance. For this reason its use is quite common for engine sizes larger than 2.5 litres, provided length of engine is not the main consideration. V-8 engines with smaller V-angles, say 20 , have also been made. The advantages of narrow V are less torsional vibrations and increased stiffness. However, the valve-operating mechanism is complicated.

SIX AND EIGHT CYLINDER ENGINES

RADIAL ENGINES : In this case the various cylinder are arranged in radial directions. About the crankshaft which is placed at the number of cylinders generally used is odd, say 5,7,9stc., To obtain uniform firing intervals. This type of engine is compact and gives higher B.H.P./ weight ratio. The construction is also simpler. However, this engine had a very large frontal area, which crests difficulty in streamlining the vehicle shape.

RADIAL ENGINES

LEFT SPRINGS WORKING

Semi-elliptic leaf spings are almost universally used for suspension in light and heavy commercial vehicles. For cars also, these are widely used for rear suspension, but now replaced completely by coil springs.

CONSTRUCTION

A rear axle leaf spring of semi-elliptic type. The spring consists of a number of leaves called blades. The blades vary in length as shown. The composite spring is passed upon the theory of a beam of uniform strength. The lengthiest blade has eyes on it's ends. This blade is called master leaf. ALL the blades are bound together by means of steel straps as shown.

The spring is supported on the axle, front or rear by means of a U-bolt. One end of the spring is mounted on the frame with as simple pin, while on the other end, connection is made with a shackle. When the vehicle comes across a projection on the road surface, the wheel moves up, deflecting the spring. This changes the length between the spring eyes. If both the ends are fixed, the spring will not be able to accommodate this change of length. This is provided for by means of a shackle at one end Which gives a flexible connection.

Rear Leaf Spring

The spring may be either cambered initially us shown flat. Highly cambered springs provide a soft suspension, but they also increase the tendency to yaw (movement about vertical axis). Flat spring reduce the tendency of the vehicle to dip, i.e. pitching, when braking or accelerating suddenly. Use of longer spring gives a soft suspension. Generally cars springs are kept longer than the front springs. This causes them to vibrate at different frequencies, which prevents excessive bounce.

Whether to have the shackle at the front rear end in case of front axle springs, is made clear by means shows the situation when the shackle is employed at the rear end. In this case the axle movement will be around the front rigid frame-spring connection, while the drag link of the steering system will have it's motion about the drag link-drop arm joint. This results in wheel wobble. If, however, the shackle is mounted on the front end as shown the axle will the have cerebrate of oration at the rear spring-eye. This gives approximately the same are as the radius action of the drag link.

Spring eyes for heavy vehicles are usually bushed with phosphor bronze bushes. However, for cars and light transport vehicles like vans, the use of rubber has also become a common practice. This obviates are necessity of lubrication as in the case of bronze bushes, where it was a necessity. The rubber bushes are quiet in operation and also the wear on pin or the bush is negligible. Moreover, they allow for slight assembly misalignment, Silent

bloc is an example of this type of bushes.

Types:

A few of the leaf springs are shown was used earlier, but these days the most widely used is semi-elliptic type the transverse spring has also been used on some vehicles. This type is the cheapest one, but bas the disadvantage that the vehicle body in this case is attached to the springs at only two places, which imparts the vehicle a tendency to roll easily when it runs fast on sharp corners.

HELPER SPRINGS:

Front Spring

Rear Spring

Spring eyes for heavy vehicles are usually bushed with phosphor bronze bushes. However, for cars and light transport vehicles like vans, the use of rubber has also become a common practice. This obviates are necessity of lubrication as in the case of bronze bushes, where it was a necessity. The rubber bushes are quiet in operation and also the wear on pin or the bush is negligible. Moreover, they allow for slight assembly misalignment, Silent

bloc is an example of this type of bushes.

Types:

A few of the leaf springs are shown was used earlier, but these days the most widely used is semi-elliptic type the transverse spring has also been used on some vehicles. This type is the cheapest one, but bas the disadvantage that the vehicle body in this case is attached to the springs at only two places, which imparts the vehicle a tendency to roll easily when it runs fast on sharp corners.

TYPES OF LEAF SPRING

HELPER SPRINGS:

Helper springs are provided on many commercial vehicles in addition to the main leaf springs. They allow for a wide range of loading. When the vehicle is only lightly loaded, these helper springs do not come into operation. But as the load is increased, they take their share of load. Generally helper springs are used on rear suspension only. the use of a helper Spring. When the load on the road wheel increases so much as to deflect the main spring to such an amount that the ends of the helper spring touch the special brackets fixed to the side member, the helper Spring comes into operation.

Helper Spring

REAR AXLE

REAR AXLE:

The differential is not shown purposely, so as to make the general arrangement more clear. The drive form the propeller shaft come to the pinion shaft which is supported in bearings in the axle casing casing. The crown wheel is in mesh with the pinion and is mounted on shaft on the ends of which are fixed the caps which serve to restrict the wheel in axial direction. The wheel are mounted on bearings on the ends of the axle shaft. In practice, however, there are two half shafts instead of single one shown here.

The weight of the body and due to occupants is transmitted through spring to the axle casing, the details of which will be described in the chapter on suspension system. The casing itself is supported by road wheels.

WEIGHT OF THE BODY:

The rear axle may be considered a beam supported at the ends and loaded at two points as shown in The rear weight W of the body is transmitted to the rear axle through two suspension springs. R1 and R2are the reaction forces form the road wheels. This weight causes shear force and bending moment in the axle shaft.

DRIVING THRUST:

Driving torque produced in the engine causes the to be produced in the road wheels, which has to be transmitted form the axle casing to the chassis frame and the body of the vehicle. the is most conveniently done by some form of member conne-cting the axle casing and the chassis frame in the longitudinal direction Such members are called thrust members or radius roads.

TORQUE REACTION:

If the road wheels are prevented from rotation with the propeller shaft rotating, it is roll round the crown wheel. The tendency is also present when the vehicle is running so climb round on the axle casing (which supports the bevel pinion), to rotate. The is called torque reaction. In the same way, the braking torque on the axle casing is opposite in direction to the torque reaction.

The tendency on the part of the axle casing has to be opposed, because, otherwise the propeller shaft would be subjected to heavy bending loads. The can be effectively done by means of a member, one and of which is attached to the axle casing and other end to the frame so that the member itself remains in the direction of the vehicle axle.

SIDE THRUST:

Often the rear axle experiences side thrust or pull due to any side load on the wheel, e.g., the cornering force. panhard rod may be employed to hold the axle in position against the side thrust.

The differential is not shown purposely, so as to make the general arrangement more clear. The drive form the propeller shaft come to the pinion shaft which is supported in bearings in the axle casing casing. The crown wheel is in mesh with the pinion and is mounted on shaft on the ends of which are fixed the caps which serve to restrict the wheel in axial direction. The wheel are mounted on bearings on the ends of the axle shaft. In practice, however, there are two half shafts instead of single one shown here.

The weight of the body and due to occupants is transmitted through spring to the axle casing, the details of which will be described in the chapter on suspension system. The casing itself is supported by road wheels.

Rear Axle

WEIGHT OF THE BODY:

The rear axle may be considered a beam supported at the ends and loaded at two points as shown in The rear weight W of the body is transmitted to the rear axle through two suspension springs. R1 and R2are the reaction forces form the road wheels. This weight causes shear force and bending moment in the axle shaft.

Body Weight on the rear axle

DRIVING THRUST:

Driving torque produced in the engine causes the to be produced in the road wheels, which has to be transmitted form the axle casing to the chassis frame and the body of the vehicle. the is most conveniently done by some form of member conne-cting the axle casing and the chassis frame in the longitudinal direction Such members are called thrust members or radius roads.

TORQUE REACTION:

If the road wheels are prevented from rotation with the propeller shaft rotating, it is roll round the crown wheel. The tendency is also present when the vehicle is running so climb round on the axle casing (which supports the bevel pinion), to rotate. The is called torque reaction. In the same way, the braking torque on the axle casing is opposite in direction to the torque reaction.

The tendency on the part of the axle casing has to be opposed, because, otherwise the propeller shaft would be subjected to heavy bending loads. The can be effectively done by means of a member, one and of which is attached to the axle casing and other end to the frame so that the member itself remains in the direction of the vehicle axle.

Radius Rods and Panhard Rod

SIDE THRUST:

Often the rear axle experiences side thrust or pull due to any side load on the wheel, e.g., the cornering force. panhard rod may be employed to hold the axle in position against the side thrust.

ENGINE SYSTEMS

Cooling systems:

This prevents the engine form overheating. It may be of air cooling or water cooling types, the former being more commonly used in smaller engine of two-wheelers, while the later types of cooling systems are predominantly used in engines of the rest of the automobiles.

This prevents the engine form overheating. It may be of air cooling or water cooling types, the former being more commonly used in smaller engine of two-wheelers, while the later types of cooling systems are predominantly used in engines of the rest of the automobiles.

Fuel system:

This includes storage tank for fuel, piping work for supply to the engine and arrangement for mixing with air and spraying into the engine cylinder.

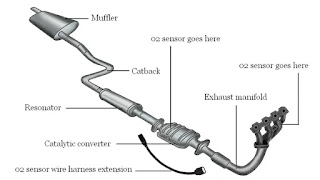

Exhaust system:

Its function is to vent exhaust gases with least back pressure and also to reduce engine noise with the help of muffler. these days converters are also fitter in the exhaust pipe to reduce the harmful constituents in the exhaust gases.

Lubrication system:

This reduces friction to decrease wear of moving parts. Relatively less viscous lubricating oils are used in engine, whereas oils and greases are used in the transmission and wheel bearings.

Ignition system:

Its function is to supply high voltage surge at the desired instant and of adequate strength to produce a spark in the engine. Earlier electro-mechanical system were systems were used, which have given was to electronic systems in modem engines.

Electrical system:

It consists of a storage battery, charging system and stating system. The battery supplies electricity for starting the engine, providing energy for spark and for all the electrical devices in the vehicle, e.g., lighting, heating, visiting, music system, etc. The charging system consists mainly of an alternator and is used to continually change the battery to keep it charger at all times. The starting system consists motor and a device to disconnect the same from the engine as soon as the engine is started.

Subscribe to:

Comments (Atom)